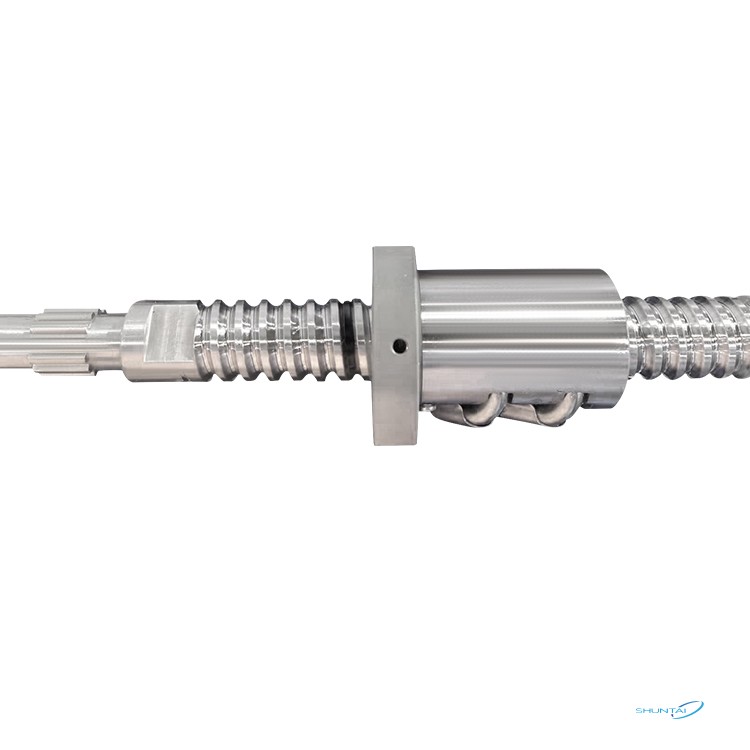

The cannulated ball screw is a common linear transmission device with the following performance features and benefits:

1. High precision: The intubated ball screw uses the combination of balls and screw threads to make the transmission more stable and precise. It can provide high positioning accuracy and repeated positioning accuracy, and is suitable for applications that require high position accuracy.

2. High rigidity: The structure of the cannulated ball screw makes it highly rigid and able to withstand large axial and radial loads. During the movement, its rigidity can remain stable and is not prone to deformation or vibration, thus ensuring the stability and accuracy of the system.

3. High efficiency: The intubated ball screw uses rolling friction. Compared with the traditional thread pair transmission method, the friction loss is smaller and the efficiency is higher. It can provide a large output torque and achieve a large movement speed with a small input torque.

4. Long life: The intubated ball screw has good wear resistance and corrosion resistance, and can operate stably for a long time in harsh working environments. At the same time, the rolling contact between the balls and the screw thread can reduce wear and extend the service life of the screw.

5. Self-locking: The intubated ball screw has self-locking performance, that is, after stopping the movement, the ball will generate a large contact pressure with the thread pair, thereby preventing the impact of external forces on the system and ensuring the maintenance and stability of the position. .

It should be noted that intubated ball screws also have some limitations, such as the need for regular lubrication and maintenance, and higher installation accuracy and axial preload control requirements. When selecting, you also need to consider the application scenarios and requirements, and comprehensively evaluate its performance and applicability.