CNC Machining Services

Technology

Technology

Advantages

Advantages

Materials

Materials

Surface Treatments

Surface Treatments

Products

Products

Overview

Overview

Order CNC machined parts online

We offer CNC machining services of varying complexity, producing both small and large batches of parts. We can provide you with a quote for CNC machining services in seconds. We test the parts we produce to ensure the quality of our products. Getting a quote for CNC machining services is easy: just upload a file of a drawing, 3D model or sketch in all common formats.

Advantages of Ordering CNC Machined Parts

| Fast Delivery | Using the new CNC machines, high-precision parts can be produced quickly within 10 days. |

| Accuracy | Wide range of tolerance options available in accordance with ISO 2768 (standard, fine) and ISO 286 (classes 8, 7, 6) |

| Customized surface treatment | Choose from a wide range of surface finishes for solid metal parts to precisely match your design specifications. |

| Material selection | Choose from more than 30 materials including metals. |

| Quality Control | Our Quality Assurance Department implements a strict quality assurance process. |

| Fast delivery | Parts can be shipped to all countries. Simply request a quote to view CNC parts pricing and shipping options. |

CNC machining materials

| Aluminum | EN AW-6060 / 3.3206 / Al-MgSi、EN AW-6061 / 3.3211 / Al-Mg1SiCu、EN AW-6082 / 3.2315 / Al-Si1Mg、EN AW-5083 / 3.3547 / Al- Mg4.5Mn、EN AW-7075 / 3.4365 / Al-Zn6MgCu |

| Steel | S45C、S50C、Q235、718、S136、SKD11、SKD61 |

| Stainless Steel | 42CrMo4、Cr12、SUS 303、SUS 304、SUS 316 |

| Copper and Brass | H62、H69、H56、H96 |

| Other | Custom |

Surface finishing options supported by CNC machining

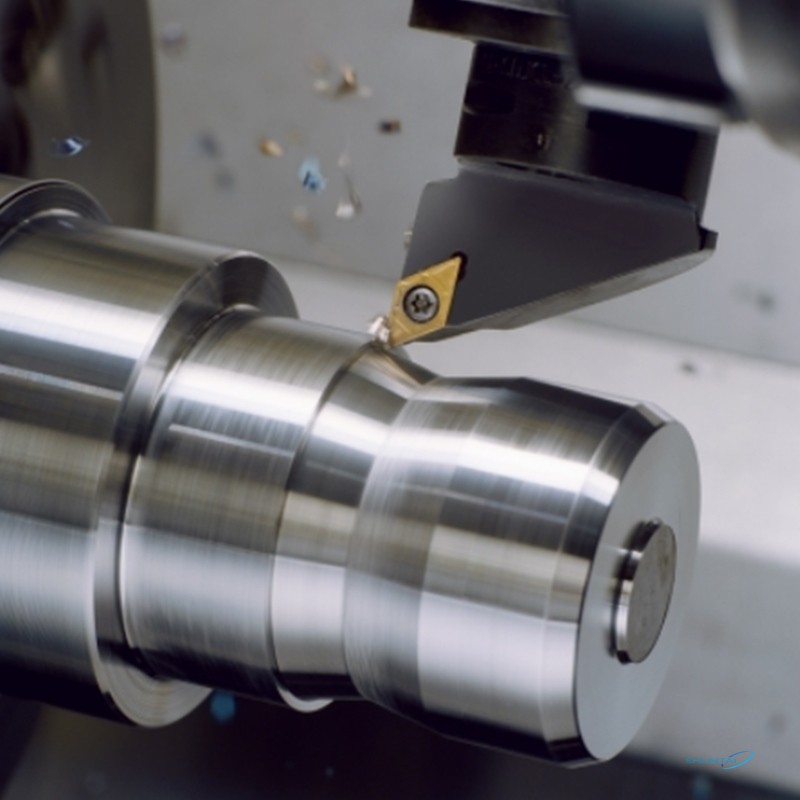

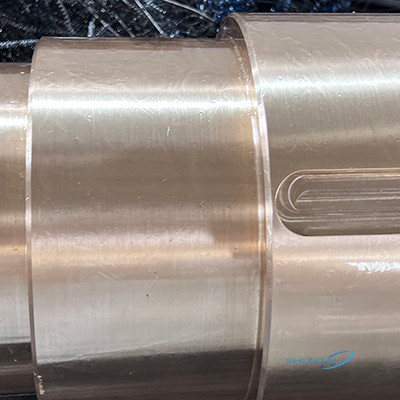

CNC Machined Parts Gallery

Example Sharing

The pictures shown below is a sharing of a case from rough embryo to finished product and then to packaging and shipment.

Contact Us

Tianlu Avenue, Lukou Street, Jiangning District, Nanjing

P: +86 17372250019 | E:zhangchaochun@njstai.com

Office Hours: 8am to 6pm