Choosing the right ball screw for your CNC machine involves considering several factors. Here are some steps to help you in the selection process:

1. Determine the application requirements: Identify the specific requirements of your CNC machine. Consider factors such as the load capacity, speed, accuracy, repeatability, and rigidity needed for your application. This will guide you in selecting the appropriate ball screw.

2. Calculate the load and speed requirements: Determine the maximum load that the ball screw will need to handle. Consider both the axial (thrust) and radial loads. Additionally, calculate the required speed at which the ball screw should travel.

3. Determine the accuracy requirements: Precision is critical in CNC machines. Consider factors like positioning accuracy, backlash, and repeatability needed for your application. This will help you determine the appropriate lead accuracy class for the ball screw.

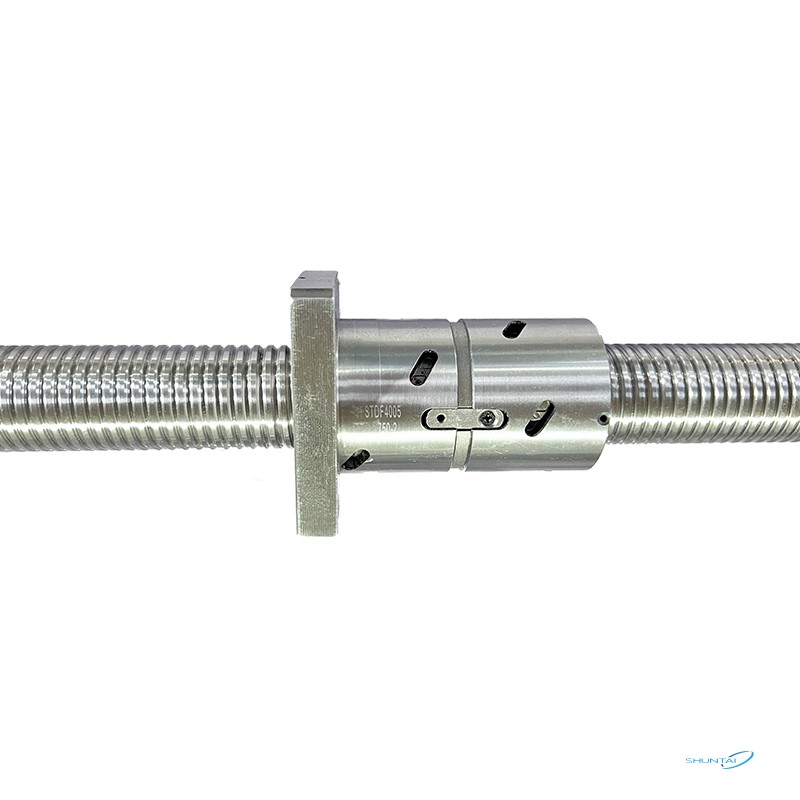

4. Identify the size and type of ball screw: Based on the load, speed, and accuracy requirements, select the appropriate ball screw size. Consider the ball screw's diameter, lead, and pitch configuration. Determine whether you need a standard or miniature ball screw, single or double nut design, and whether to use a preloaded or non-preloaded configuration.

5. Consider the life and maintenance requirements: Determine the desired service life of the ball screw and consider the required maintenance procedures. Evaluate factors such as lubrication requirements, regreasing intervals, and overall maintenance costs.

6. Evaluate environmental conditions: Consider the operating environment of your CNC machine. Factors such as temperature, dust, vibrations, and contaminants can affect the performance and durability of the ball screw. Select a ball screw with appropriate sealing and coating options to ensure reliability in the given conditions.

7. Seek manufacturer recommendations and support: Contact reputable ball screw manufacturers or suppliers for their recommendations. Provide them with accurate information about your machine's specifications and requirements. They can help guide you towards the most suitable options and provide valuable technical support.

8. Consider cost and availability: Finally, assess the cost and availability of the ball screw options. Compare prices from different manufacturers and distributors while ensuring that you are getting a reliable and high-quality product.

Remember, ball screw selection is a critical decision, and seeking expert advice from manufacturers or suppliers with experience in CNC applications is highly recommended to ensure optimal performance and longevity of your CNC machine.