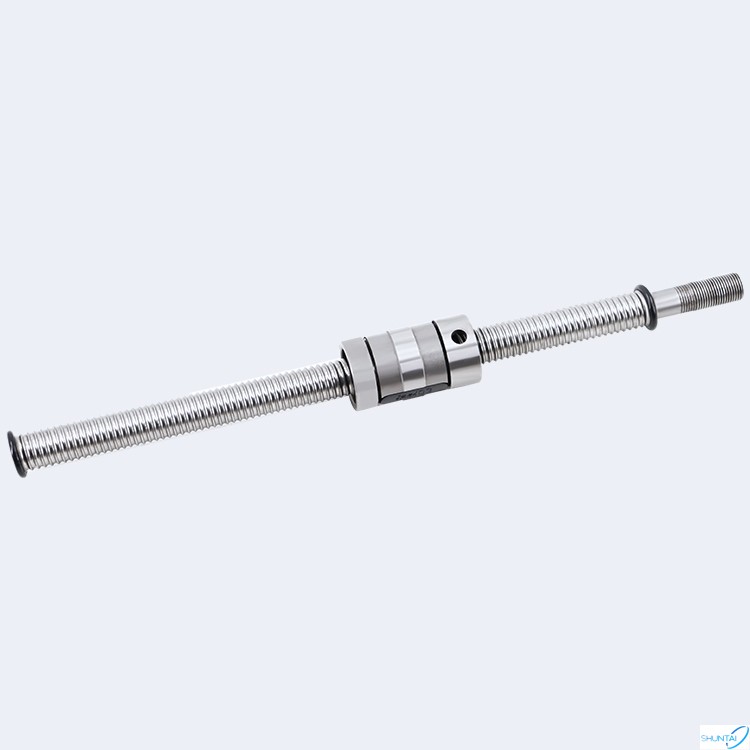

Non-standard ball screws are relative to standard size ball screws, and they may differ from standard ball screws in shape, size, material and manufacturing process. Non-standard ball screws are often custom-made for specific needs and applications to meet special engineering requirements.

The application scenarios of non-standard ball screw include but not limited to the following aspects:

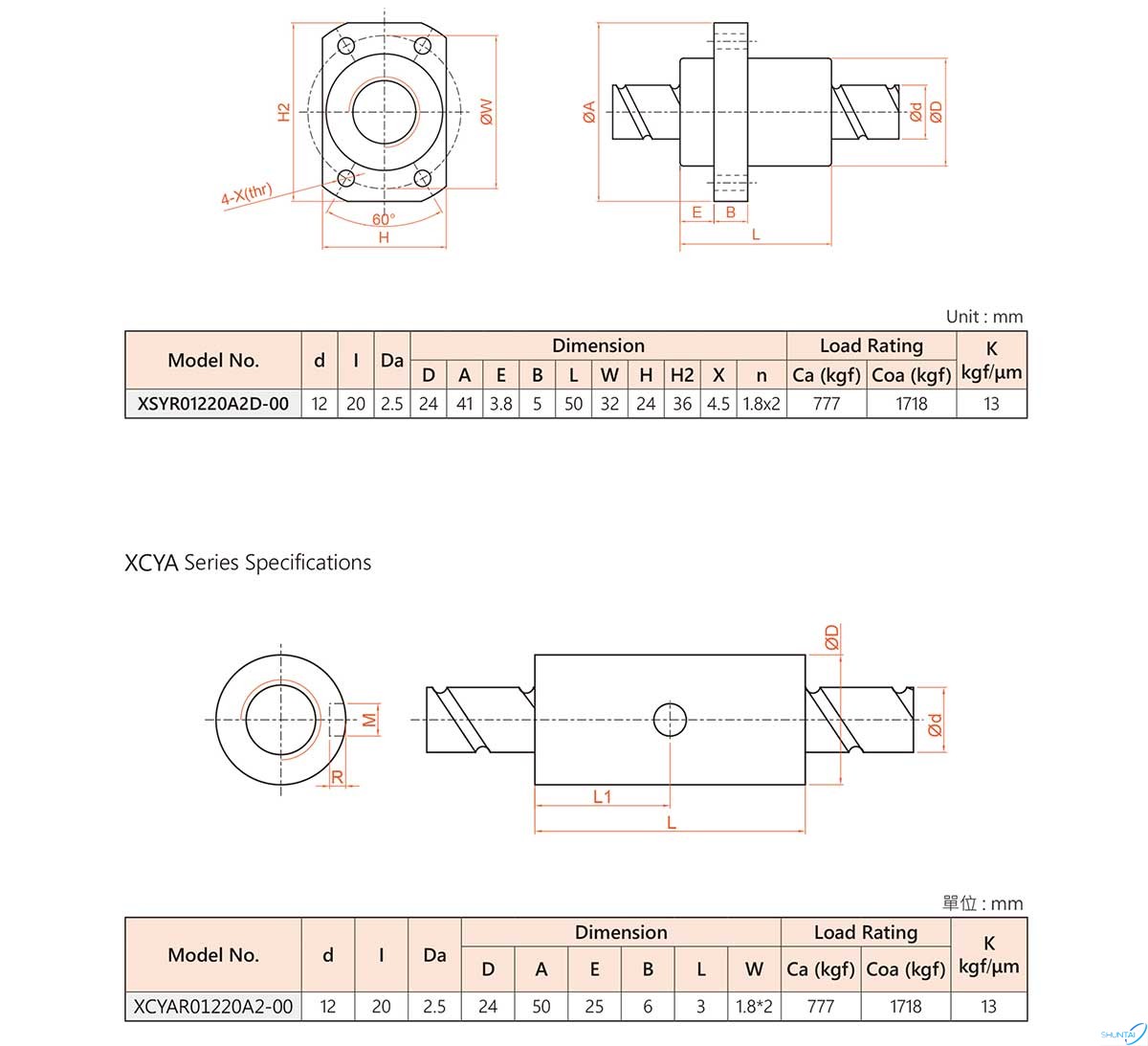

Special size requirements: In some applications, due to space constraints or other factors, it is necessary to customize the size parameters of the ball screw such as length, diameter, and pitch.

Special material requirements: Non-standard ball screws can use special materials to meet the needs of specific environments, such as stainless steel, high-temperature wear-resistant materials, etc.

High load or high-speed requirements: Some applications need to withstand larger loads or high-speed movement, non-standard ball screws can be designed and processed according to requirements to provide higher load carrying capacity and movement speed.

Special manufacturing process requirements: Non-standard ball screws may require special manufacturing processes to meet specific application requirements, such as special processing methods or surface treatment processes.

Customization of non-standard ball screws usually requires cooperation with professional ball screw manufacturers or suppliers, who can provide customized design, processing and manufacturing services according to specific requirements of customers. By customizing non-standard ball screws, we can meet the special application requirements of various engineering fields and improve system performance and efficiency.