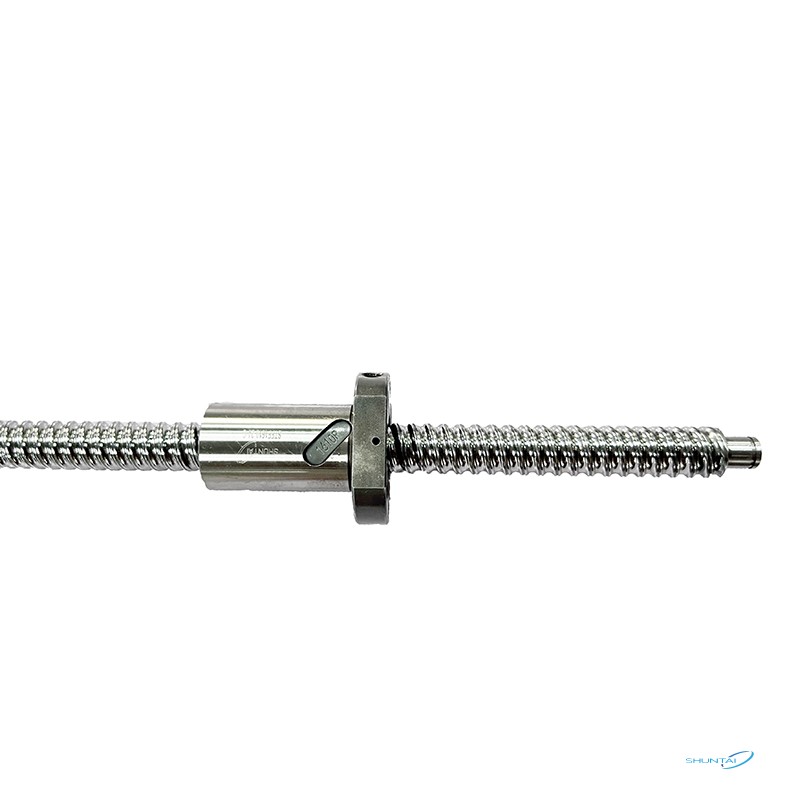

Rolled ball screw is a ball screw manufacturing process with the following characteristics:

1. High precision: The manufacturing process of the rolled ball screw can achieve higher processing accuracy, making it have lower rotation error and smaller clearance, and can provide higher positioning accuracy and repeated positioning accuracy.

2. High stiffness: The rolled ball screw adopts a certain process to make the contact area between the ball and the screw larger, which can provide higher stiffness and anti-vibration performance, which is beneficial to improving the working accuracy and stability of the mechanical system. sex.

3. High efficiency: The rolled ball screw can achieve low friction loss and energy loss between the balls and the screw, and can provide high transmission efficiency, so it is suitable for application scenarios that require high-speed motion and high-efficiency transmission.

4. Long life: The rolled ball screw uses high-quality ball and screw materials, and adopts advanced heat treatment and surface treatment processes, which can provide high wear resistance and corrosion resistance, thus extending the service life of the ball screw. .

Usage scenarios for rolled ball screws include:

1. CNC machine tools: In CNC machine tools, rolled ball screws can be used for motion transmission of each axis to achieve high-precision and efficient positioning and motion control.

2. Automation equipment: In automation equipment, rolled ball screws can be used in robots, printing machines, packaging machines and other equipment that require high-precision and high-speed motion transmission to improve production efficiency and product quality.

3. Automobile industry: Rolled ball screws can be used in seat adjustments, door switches, sunroof controls and other components in automobile manufacturing to provide precise motion control and adjustment.

4. Aerospace: In aerospace applications such as aircraft and satellites, rolled ball screws can be used for the transmission and control of mechanical devices such as servos, doors, and landing gears to meet the requirements of high precision and reliability.

In short, due to its high precision, high stiffness, high efficiency and long life, rolled ball screws are widely used in many industrial fields that require precision motion transmission and control.