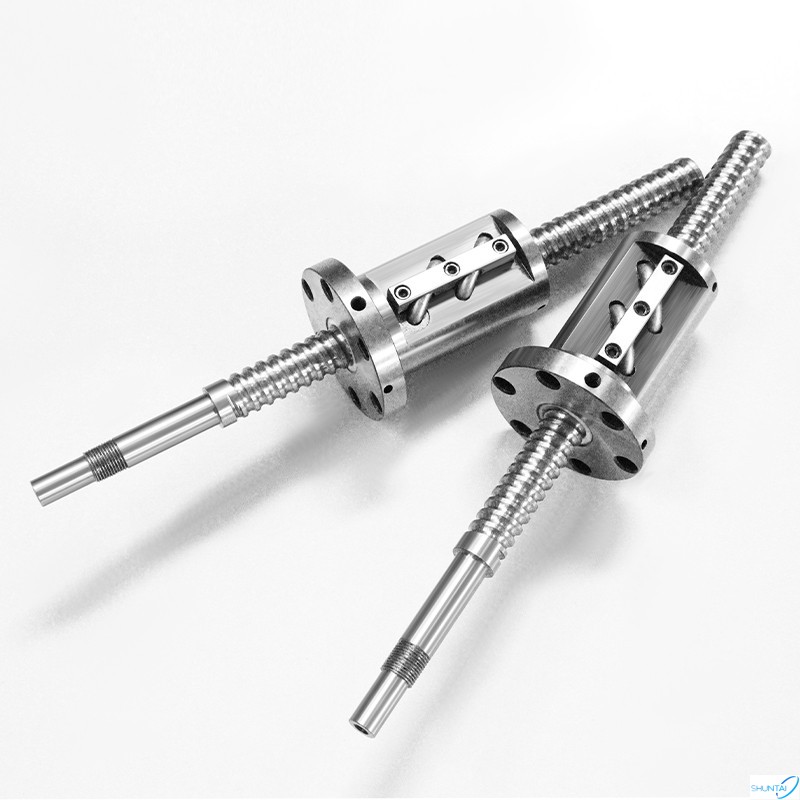

External Threaded Screw is a mechanical transmission device consisting of a threaded rod (screw) and a nut. The threaded rod has external threads, and the nut has matching internal threads. When the threaded rod rotates, the nut moves axially along the threaded rod, converting to linear motion. The rotational motion of the threaded rod is converted into linear motion of the nut.

External circulation screws are widely used in various mechanical systems, such as CNC machine tools, lifting platforms, conveying machinery, etc. They are typically used in applications requiring precise transmission and position control.

The characteristics of the external circulation screw include:

1. Accuracy: The external circulation screw has high transmission accuracy and can achieve precise motion control and positioning.

2. Load capacity: External circulation screws usually have high load carrying capacity and can withstand large axial loads.

3. Smooth movement: Due to the design of the outer circulation screw, its movement is relatively smooth and noise-free.

4. Reverse resistance: The external circulation screw has high resistance characteristics, which can prevent the load from falling freely when a power outage or mechanical failure occurs.

It should be noted that the outer circulation screw moves slowly and may generate wear and heat during long-term operation. Therefore, when selecting and using an external circulation screw, factors such as load requirements, movement speed, lubrication and maintenance need to be considered.

In general, the external circulation screw is a reliable, stable and precise mechanical transmission device, suitable for applications that require linear motion conversion, especially in systems that require higher position control and precision transmission.