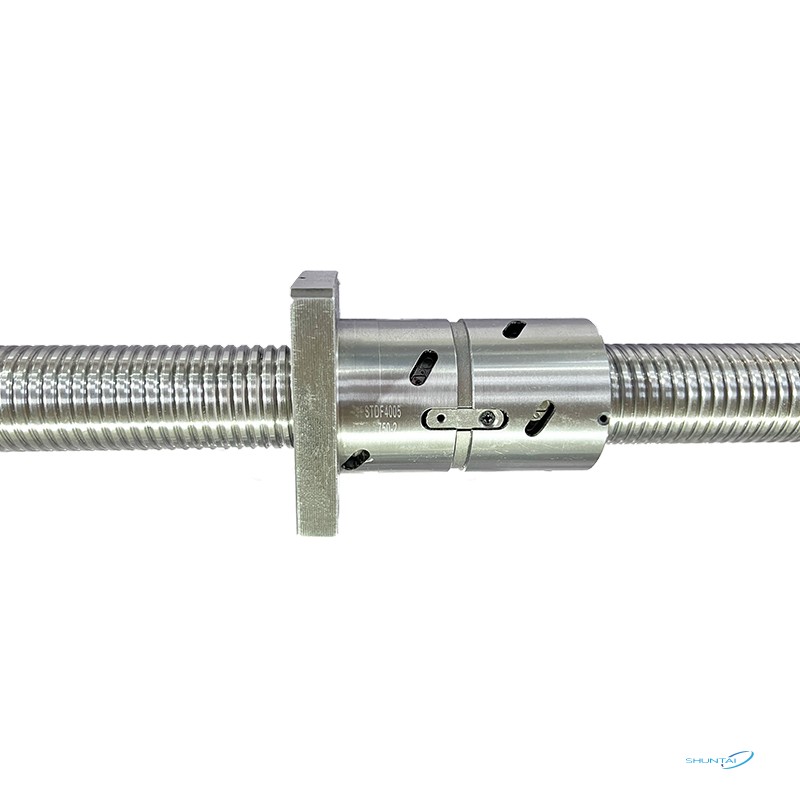

We have more than 1000 kinds of linear guide and ball screw and other mechanical parts, and support customized products for customers, pls free to contact us if you have any needs.

Nowadays, the application range of ball screws and linear guides is expanding day by day with the rapid development of science and technology. The following introduces main six main application scenarios.

In the field of precision mechanical transmission, the length-to-diameter ratio has always been a key indicator of manufacturing capability. Recently, our company successfully completed the production and acceptance of an 8-meter-long high-precision ball screw, which was then smoothly shipped to the customer's site. I. Precision Elimination: Rigorous Pre-shipment Inspection For an 8-meter-long ball screw, straightness and lead accuracy are the core of quality control. Laser Interferometer Testing: In a temperature-controlled workshop, we used a laser interferometer to scan the cumulative representative lead deviation along the entire length, ensuring it meets the customer's required C3/C5 precision standards. Radial Runout Monitoring: Utilizing a multi-point support testing method, we strictly control radial runout over long distances to prevent vibration during high-speed rotation. II. Core Challenges: Deformation-Preventing Packaging for Extra-Long Parts Segmented Support and Fixing: We customized reinforced wooden packaging boxes with U-shaped support positions at regular intervals inside, lined with high-density shock-absorbing cotton, to evenly distribute the weight on the ball screw and prevent permanent plastic deformation. Multi-layer Protection Process: Rust-proof Layer: Sprayed with high-grade, long-lasting rust-preventive oil. Sealing Layer: Tightly wrapped with vacuum film to isolate air and moisture. Anti-collision Layer: Wrapped with multiple layers of bubble wrap and corner protectors to prevent bumps and knocks during hoisting. III. Logistics and Transportation The 8-meter-long cargo box places higher demands on transport vehicles and lifting equipment. Hoisting Scheme: Employing dual overhead cranes or multi-point balancing slings ensures the container remains level when entering the container or truck, strictly prohibiting single-point lifting that could cause breakage or bending of the internal screw rods. Logistics Tracking: Dispatching an experienced specialized transport fleet, planning routes to avoid congestion and poor road conditions, and providing real-time monitoring along the entire route. IV. Special Reminders for Customers After receiving this batch of 8-meter-long screw rods, please pay attention to the following: Unloading Inspection: Observe the wooden crate for obvious signs of breakage or deformation. Vertical Storage: If not installed immediately, vertical hoisting and storage are recommended. If horizontal storage is necessary, please retain the original packaging and ensure the ground is flat. Do not place heavy objects in the center of the lead screw. Installation and Calibration: During installation, extra-long lead screws must be finely adjusted using high-precision guide rails to achieve optimal transmission performance. The successful delivery of each 8-meter lead screw not only represents a breakthrough in our ultra-long stroke machining technology but also reflects our relentless pursuit of precision.

+

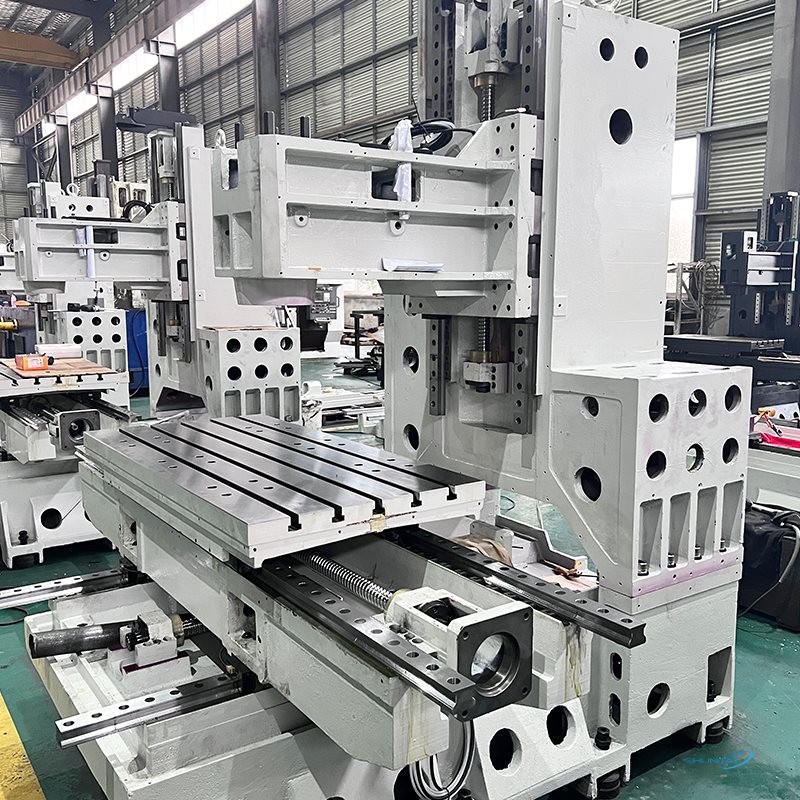

The Lead screw Grinding machine adopts advanced CNC system, high-precision sensors and automation functions. It has the advantages of high speed, high precision, high rigidity and multi-function. We have added more machines and equipment for manufacturing ball screws on the original basis, just to guarantee the best product quality and on-time work efficiency to our customers. Cooperate with us Shuntai and win together!

+

Choosing the right ball screw for your CNC machine involves considering several factors. Here are some steps to help you in the selection process: 1. Determine the application requirements: Identify the specific requirements of your CNC machine. Consider factors such as the load capacity, speed, accuracy, repeatability, and rigidity needed for your application. This will guide you in selecting the appropriate ball screw. 2. Calculate the load and speed requirements: Determine the maximum load that the ball screw will need to handle. Consider both the axial (thrust) and radial loads. Additionally, calculate the required speed at which the ball screw should travel. 3. Determine the accuracy requirements: Precision is critical in CNC machines. Consider factors like positioning accuracy, backlash, and repeatability needed for your application. This will help you determine the appropriate lead accuracy class for the ball screw. 4. Identify the size and type of ball screw: Based on the load, speed, and accuracy requirements, select the appropriate ball screw size. Consider the ball screw's diameter, lead, and pitch configuration. Determine whether you need a standard or miniature ball screw, single or double nut design, and whether to use a preloaded or non-preloaded configuration. 5. Consider the life and maintenance requirements: Determine the desired service life of the ball screw and consider the required maintenance procedures. Evaluate factors such as lubrication requirements, regreasing intervals, and overall maintenance costs. 6. Evaluate environmental conditions: Consider the operating environment of your CNC machine. Factors such as temperature, dust, vibrations, and contaminants can affect the performance and durability of the ball screw. Select a ball screw with appropriate sealing and coating options to ensure reliability in the given conditions. 7. Seek manufacturer recommendations and support: Contact reputable ball screw manufacturers or suppliers for their recommendations. Provide them with accurate information about your machine's specifications and requirements. They can help guide you towards the most suitable options and provide valuable technical support. 8. Consider cost and availability: Finally, assess the cost and availability of the ball screw options. Compare prices from different manufacturers and distributors while ensuring that you are getting a reliable and high-quality product. Remember, ball screw selection is a critical decision, and seeking expert advice from manufacturers or suppliers with experience in CNC applications is highly recommended to ensure optimal performance and longevity of your CNC machine.

+

Ball screws are widely used in pharmaceutical machinery. Ball screw is a device that converts rotary motion into linear motion. It has the characteristics of high precision, high speed and high load capacity, and is suitable for applications that require precise control of position and speed. In pharmaceutical machinery, ball screws are mainly used in the following aspects: 1. Tablet press: The tablet press in the pharmaceutical manufacturing process needs to compress pharmaceutical powder into tablets. Ball screws can be used to control the movement of the upper and lower molds to ensure precise pressure and motion control during the pressing process, thereby ensuring tablet quality and stability. 2. Pulverizer: Pulverizer in the pharmaceutical process is used to crush raw materials into the required particle size. The ball screw can drive the feeding device of the crusher, control the feed speed and particle size of raw materials, and achieve precise control of the crushing process. 3. Packaging machine: The packaging process of pharmaceutical products requires precise position control and motion control. Ball screws can be used in the conveying device, clamping device and other components of packaging machines to ensure precise movement and positioning during the packaging process and improve packaging efficiency and quality. 4. Conveying device: Conveying devices in pharmaceutical production lines often need to accurately convey raw materials or finished products to designated locations. Ball screws can be used to control the movement of conveyor belts to achieve accurate position control and adjustment. In short, ball screws are widely used in pharmaceutical machinery, providing precise position control, speed control and load capacity, helping pharmaceutical companies achieve efficient and stable production processes. --

+

As an important part of the transmission system, the ball screw has a vital impact on the performance and accuracy of the 3D printer. It is one of the important parts of 3D printer. The advantages of using ball screws in 3D printers mainly include the following aspects: 1.High precision: The ball screw has high precision and high rigidity, which can achieve precise positioning and stable movement of the 3D printer print head, thereby improving printing accuracy. 2.High stability: The ball screw transmission method has high stability, which can reduce errors and vibrations during the printing process and ensure printing consistency and stability. 3.Efficiency: The ball screw has high transmission efficiency, which can increase the printing speed of the 3D printer and shorten the printing time. 4.Easy to maintain: The ball screw has a simple transmission structure and is easy to maintain, which can reduce the maintenance cost and failure rate of 3D printers. To sum up, ball screws used in 3D printers have the advantages of high precision, high stability, high efficiency and easy maintenance. They can improve printing quality and efficiency and reduce maintenance costs and failure rates.

+

Miniature ball screws are widely used in various fields. Here are some main application fields: Machinery manufacturing: Micro ball screws are usually used in small mechanical devices, such as small machine tools, precision instruments, robots, etc. Optical equipment: Micro ball screws are often used in optical equipment such as focusing mechanisms, optical platforms, and optical telescopes to achieve precise optical system adjustment. Electronic equipment: Micro ball screws are used in various electronic equipment, such as electron microscopes, semiconductor equipment, R&D and production of electronic components, etc. Medical equipment: Micro ball screws are widely used in medical equipment, such as surgical instruments, robotic surgical systems, imaging diagnostic equipment, etc. Automotive industry: Micro ball screws are mainly used in the automotive industry for car seat adjustment, door and window opening and closing, steering wheel adjustment and other functions. In addition to the above application fields, miniature ball screws can also be used in precision measurement equipment, aerospace, military and other fields. Because the advantages of miniature ball screws include high precision, high load capacity, long life, etc., they are widely used in situations where precise positioning and adjustment are required.

+

Factory Area Covers (square meters)

Professional Personnels

Production Lines

Country Of Cooperation

This section will continue to update the latest news and technological development of ChunXin company in the machinery industry for you, looking forward to progress and growth with you.

2025-11

2025-09

2025-09

2025-07